Bearing vs slip critical connections is little bit confusing question ❓ In this article you will have clear idea about bearing and slip critical connections. Bolted structural steel connections are one of the most common connection types in structures due to their low cost and efficient installation.

Bolted connections transfer force between two connected members through either the dowel action of a bolt or through friction in the connection. The American Institute of Steel Construction (AISC) specifies two performance categories for high-strength bolted connections:

|

| Fig 2: N-type X-type bolts |

- Bearing-type connections

- Slip-critical connections

Bearing-type connection

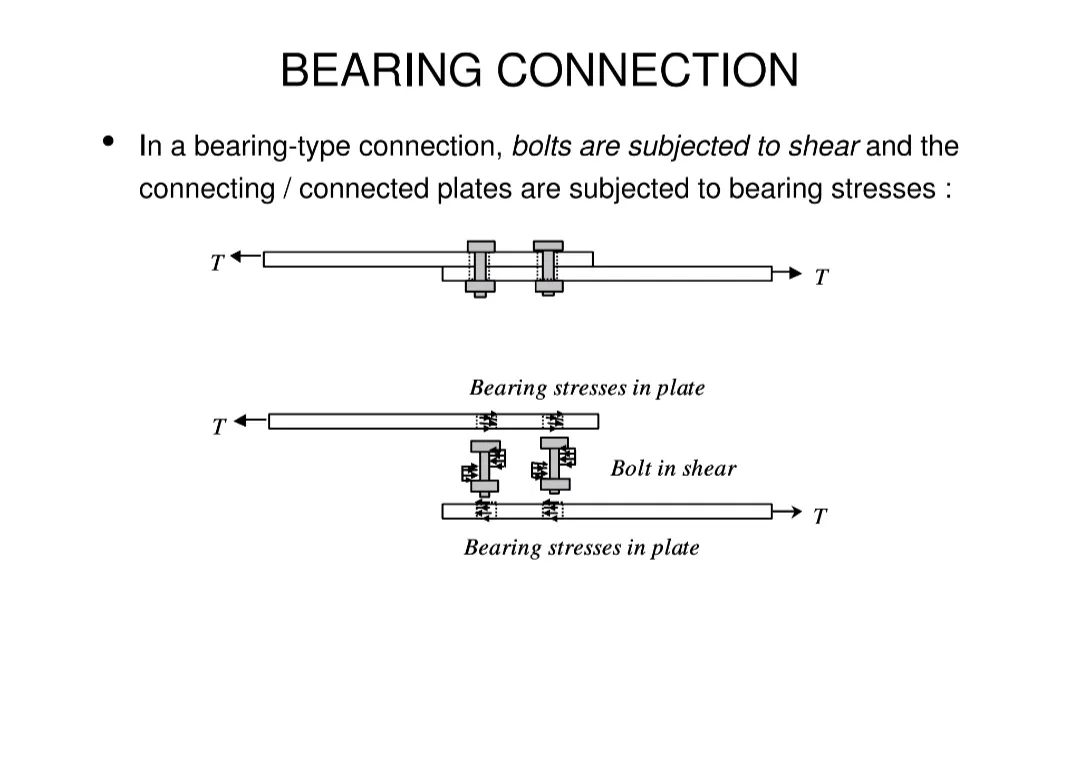

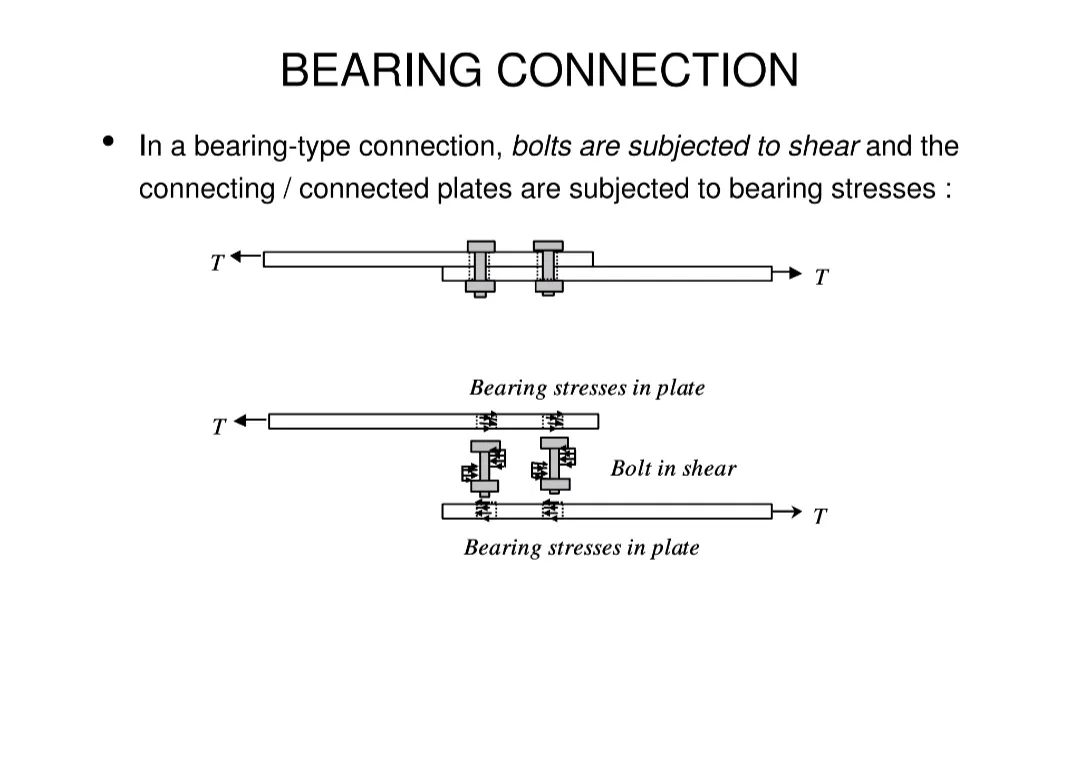

Bearing-type connections are among the simplest means of transferring external force from one joint member to another. Bearing-type connections rely only on the bolt shank to transfer an applied force from one joint member to the other.

Bolts in a bearing-type connection are typically tightened only enough to keep the joint members in full contact. Therefore, in a bearing-type connection, the effects of friction between the plates are negligible.

|

| Fig.1: Bearing-type connection |

Fig. 1 shows a bearing-type connection of a lap joint and the associated free body diagrams of each component. The free body diagram of the bolt shank demonstrates that the applied load, P, is transferred from plate to plate through shear in the bolt.

Because applied load, P, creates an unbalanced moment and the bolt holes are slightly larger than the nominal diameter of the bolt, some minor rotation of the bolt will occur, creating both tension and shear in the bolt shank. However, the induced tension in the bolt is generally negligible compared to the shear.

Bearing-type connection is further classified into two types. The threads of a bolt may either be included (N bolts) in the shear plane or excluded (X bolts) from the shear plane.

- N type: Bearing type connection where the threads of the bolt are included in the shear plane.

- X type: Bearing type connection where the threads of the bolts are excluded from shear plane.

The shear plane is the plane between two or more pieces under load where the pieces tend to move parallel from each other, but in opposite directions.

The most commonly used bolt is an ASTM A325N 3/4"bolt with the threads included in the shear plane.

Slip critical connection

Slip-critical connections do not rely on bearing between the plate and the bolt to transfer the load between joint members. Instead, pre-tensioning of the bolt creates a clamping force between the connected members and the joint relies on friction to transfer the load between joint members.

|

| Fig. 3: Slip critical connection |

Slip-critical connections are often used to prevent fatigue failure of the bolt in cases where the direction of the load frequently changes. Fig. 3 shows a slip-critical connection and the associated free body diagrams of the components. The pretension in the bolt compresses the joint members together.

The resulting frictional forces provide the resistance necessary to prevent plates from sliding past one another and the plates from bearing on the bolt.

The "turn of the nut" method is also widely used to achieve that state of friction. The faying surfaces of slip-critical connections must be properly prepared in order to maximize friction forces between the surfaces joined. Usually, this requires cleaning, descaling, roughening, and/or blasting of the faying surfaces. Painting the faying surfaces with a class B primer also allows being in accordance with most of the design that asks for Slip-critical joint.

When to use Slip critical joints

Per the RCSC Specification (RCSC 2009), Slip-critical joints are only required in the following applications involving shear or combined shear and tension:

- Joints that are subject to fatigue load with reversal of the loading direction.

- Joints that utilize oversized holes.

- Joints that utilize slotted holes, except those with applied load approximately normal (within 80 to 100 degrees) to the direction of the long dimension of the slot.

- Joints in which slip at the faying surfaces would be detrimental to the performance of the structure.

Slip Critical Connections are expensive because of faying surface preparation, tightening and inspection requirements.

SC-Connections are not needed for typical framing connections and most moment connections and bracing connections.SC-Connections may be needed when dynamic or vibration loads are present or may be used to control drift in frames and are required in some moment connections.