Types of weld in steel structures: Structural welding is a process by which the parts that are to be connected are heated and fused, with supplementry molten metal at the joint. A welding joint is a point or edge where two or more pieces of metal are joined together. They are formed by welding two or more workpieces (metal) according to a particular geometry.

There are five types of joints referred to by the American Welding Society (AWS) which are butt joint, lap joint, corner joint, edge joint and tee joint. In the field of steel structure fabrication and installation, arc welding is widely used.

Also see: How to understand welding symbols in steel detailing

|

| Fig 1: Types of weld joints |

Basic types of weld in steel structures

- Fillet weld

- Groove weld or butt weld

- Slot and plug weld

Fillet weld

|

| Fig 2: Fillet weld |

The most common type of weld used for building structures is the "fillet" weld, which joins pieces at right angles. Fillet welds are typically more economical than groove welds due to less edge preparation.

The significance of the weld symbol’s position on the reference line is depicted in below figure 3.

|

| Fig 3: Significance of weld symbols position |

Groove weld

Groove weld is provided when members to be joined are lined up. It is costlier since it requires surface preparation. Groove welds are most commonly applied to butt joints and consist of the following types.

- Partial joint penetrations (PJP)

- Complete joint penetrations (CJP)

- Flare-bevel groove welds

Groove welds can be partial joint penetration (PJP) or complete joint penetration (CJP) depending on the strength requirements.

|

| Fig 4: Groove welds types CJP and PJP |

Partial Joint Penetration weld

Complete Joint Penetration weld

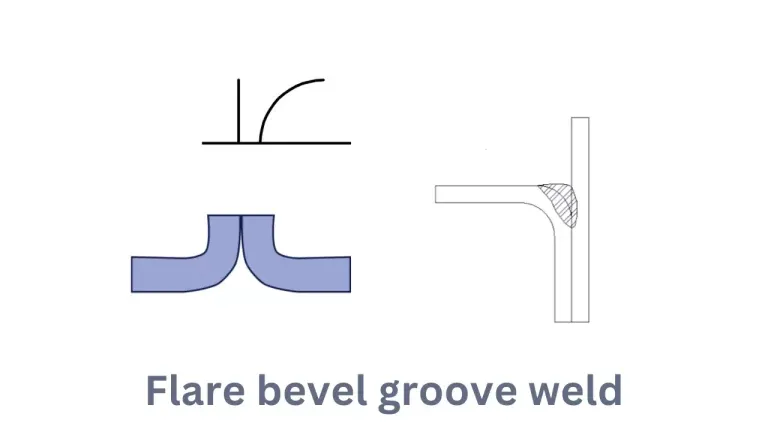

Flare bevel groove weld

It is the type of weld which is used to connect a round surface and a planar surface.For instance, you want to connect a round pipe having some radius with a planar surface like a flat bar. For such cases, then you should use this type of weld to get a nice and clean finishing.

|

| Fig 5: Flare bevel groove weld |

Recommended for you: Exploring the Various Types of Weld Positions

Slot and plug weld

Don’t miss: Stitch welding in steel structure