Stitch welding is intermittent weld. It involves initiating a weld, welding for a portion of the joint length, terminating the weld, and then starting again along the joint a specified distance from the previous weld. Stitch Welding is also called as skip welding.

They are placed in three different ways:

- Intermittent Weld: Stich welds are placed only on one side of the joint.

- Chain Intermittent Weld: Stich welds are placed on both sides of the joint.

- Staggered Intermittent Weld: Stich welds are placed on both sides of the joint by offsetting each other weld.

|

| Fig 1: Chain Intermittent welds |

|

| Fig 2: Staggered Intermittent welds |

You might also like: Types of weld in steel structures

What is pitch in stitch welding?

The pitch is the center-to-center distance of each of the weld segments. It is shown to the right of the length on the welding symbol, with a dash between the two.

The weld length is the linear distance of each weld segment. The length is shown in the welding symbol to the right of the weld symbol.

Don't miss: How to understand welding symbols in steel detailing

Stitch welding types

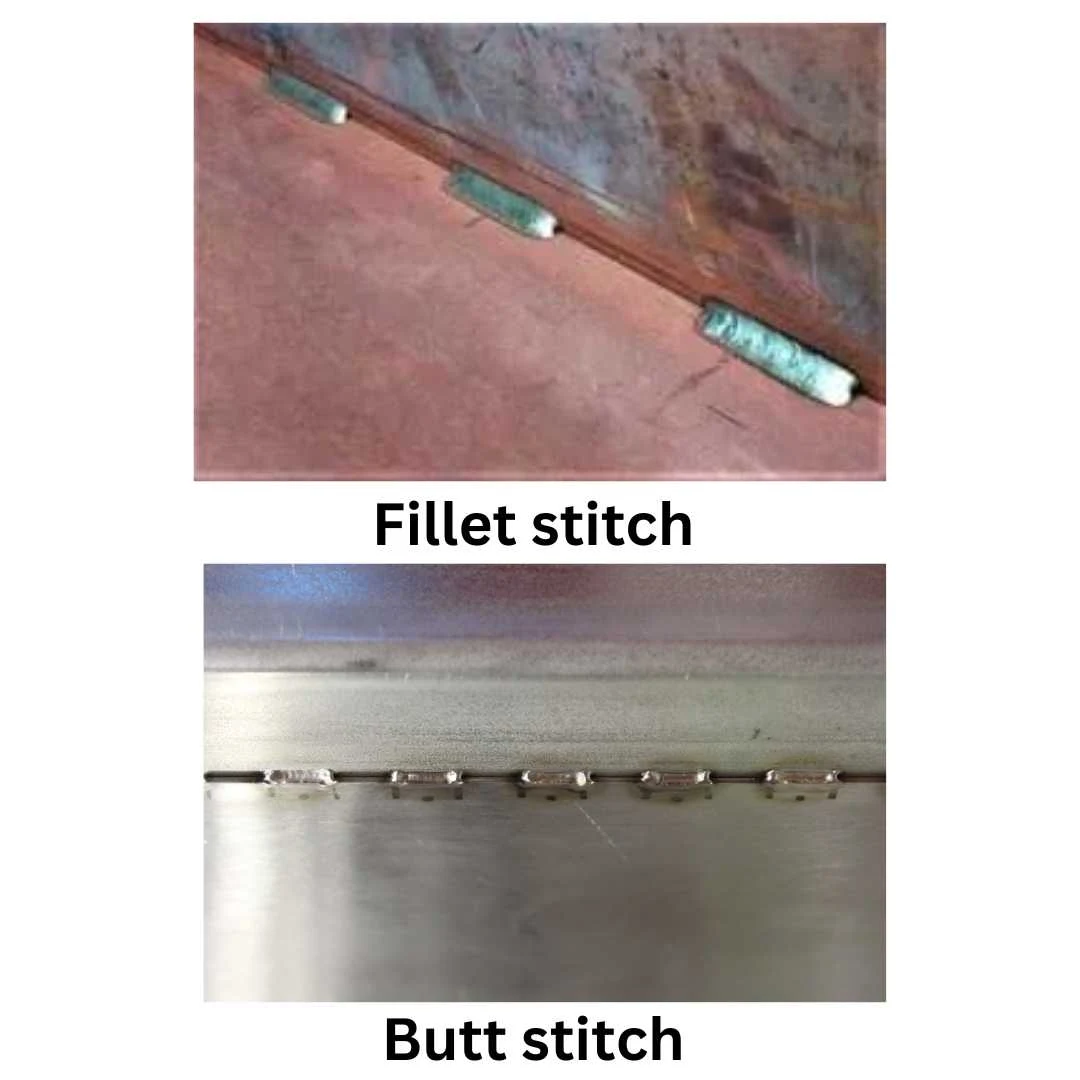

There are two common types of stitch welds, fillet weld and butt joint weld. Flare bevel groove weld is also used in some cases.

|

| Fig 3: Stitch welding types |

Stitch welding application, Advantages and Disadvantages

Stitch welding used to prevent heat distortion and to also reduce the cost of welding if a long continuous weld is not necessary. It also means less filler metal is used, which saves money, and the weld is usually completed in less time than if it was continuous.

Featured: Understanding Minimum Weld Sizes for Plate Thickness: AISC Guidelines Explained

Stitch welding does have some disadvantages. When the overall weld length is reduced, this oftentimes comes with a reduction in the strength of the weld joint. Also, the portions of a weld joint that are left unwelded could be in the form of a crevice. This crevice may accumulate foreign material that could increase the corrosion rate of the base material.